Snow blower maintenance tips: Top 3 Essentials

Why Snow Blower Maintenance is Critical for New England Homeowners

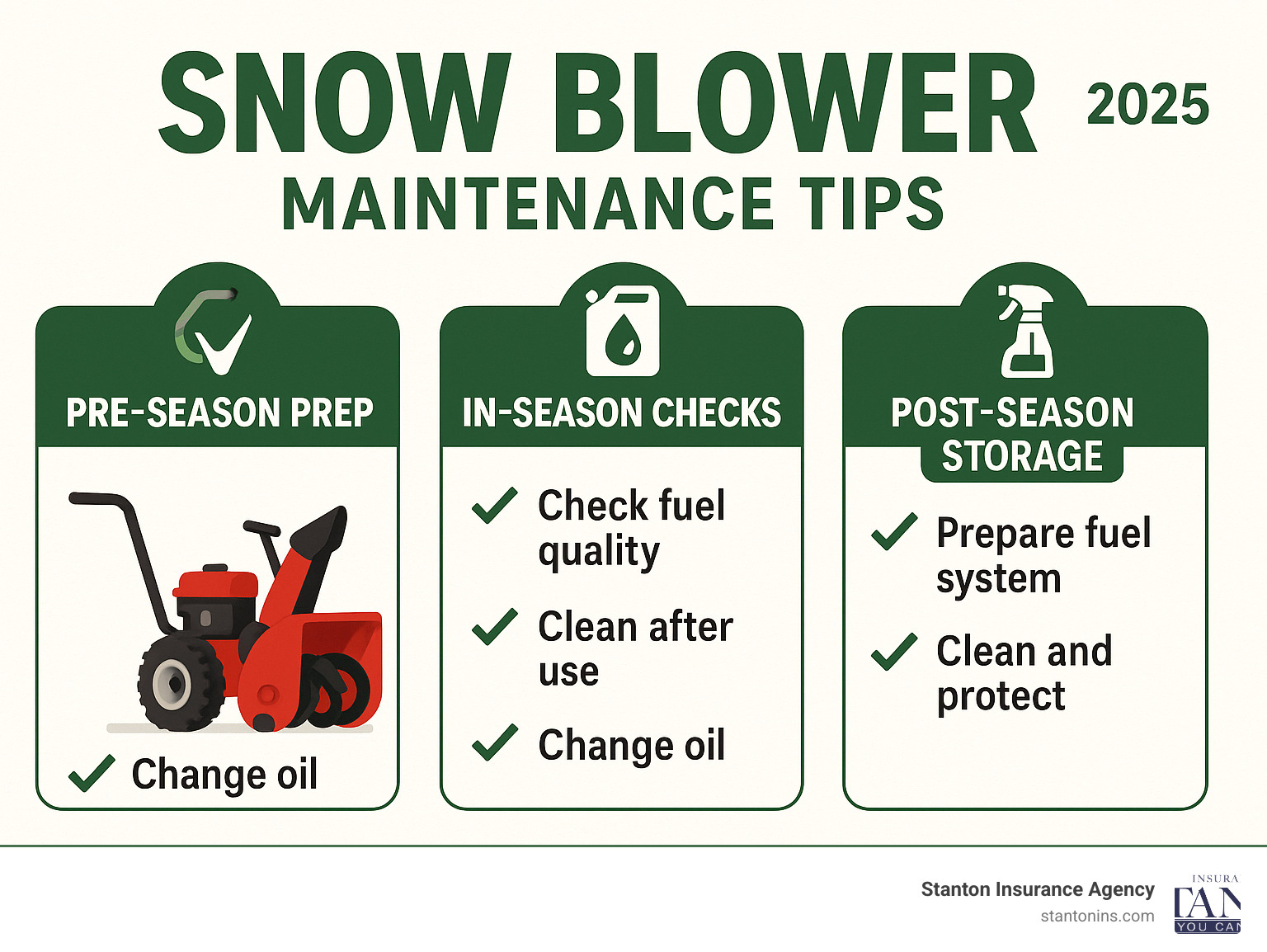

Snow blower maintenance tips are essential for keeping your machine running when you need it most. Regular maintenance prevents costly repairs, ensures reliable starts during blizzards, and extends your equipment’s lifespan. Proper preparation is key to avoiding winter nightmares.

Essential Snow Blower Maintenance Tips:

- Change oil annually (after first 5 hours on new machines, then once per season)

- Use fresh fuel with stabilizer (fuel degrades in 30 days without treatment)

- Replace spark plug every 100 hours or once per season

- Check belts for cracks and fraying before each season

- Inspect scraper bar and skid shoes for wear

- Keep spare shear pins on hand for two-stage models

- Clean machine after each use to prevent rust and corrosion

- Store properly with fuel system preparation

When a blizzard hits Massachusetts or New Hampshire, you need your snow blower to start on the first pull. A well-maintained machine clears driveways efficiently and safely.

I’m Geoff Stanton of Stanton Insurance Agency. Through years of helping homeowners protect their valuable assets, I’ve seen how proper equipment maintenance prevents costly claims and keeps families safe during harsh New England winters. These snow blower maintenance tips will help you avoid the frustration of a dead machine when heavy snow is in the forecast.

Snow blower maintenance tips vocab to learn:

Your Pre-Season Checklist: Getting Ready for the First Snowfall

Before the first flakes fly, a thorough check-up ensures your machine is ready to tackle a harsh Massachusetts winter. This initial inspection prevents the stress of a non-starting machine on a snowy morning.

Start by pulling out your snow blower’s operator’s manual for model-specific instructions. Next, inspect and tighten all nuts, bolts, and screws, as vibrations can loosen them over time. Finally, check the tire pressure, which should typically be between 15 to 20 PSI. Proper tire pressure ensures good traction in heavy New England snow. Taking these simple steps will ensure your snow blower is in top shape. For more tips on preparing your home for the colder months, visit our guide on Prepare Home for Winter.

Single-Stage vs. Two-Stage Maintenance Differences

Understanding your machine is the first step. Single-stage blowers are simpler, while two-stage models have more components requiring attention. A single-stage blower uses one auger to collect and throw snow, while a two-stage model uses an auger to feed snow into a high-speed impeller that discharges it. This design allows two-stage models to handle deeper, heavier snow. Electric models require less maintenance but still need checks on augers and scraper bars.

Here’s a quick comparison of their typical maintenance considerations:

| Feature | Single-Stage Snow Blowers | Two-Stage Snow Blowers |

|---|---|---|

| Auger Type | Rubber paddles (contact ground) | Steel auger (does not contact ground), plus an impeller |

| Belts | One drive belt | Two belts (one for auger, one for drive) |

| Ground Contact | Auger paddles clear snow to pavement | Skid shoes adjust clearing height, protecting surfaces |

| Safety Feature | Less common, direct drive. | Shear pins (sacrificial bolts protecting gearbox) |

| Key Maintenance | Inspect/replace rubber paddles, check single belt, inspect scraper bar. | Inspect/lubricate steel auger, check two belts, adjust/replace skid shoes, inspect/replace shear pins, lubricate gearbox. |

| Complexity | Generally simpler, less parts to maintain. | More complex, more moving parts, requires more detailed lubrication. |

Inspecting Wearable Parts

Key components are designed to wear down with use. Checking them before the season saves you from a mid-storm breakdown.

- Scraper Bar: This strip along the bottom of the auger housing scrapes snow off the surface. If your machine leaves a thin layer of snow, your scraper bar is likely worn and needs replacement.

- Rubber Auger Paddles (Single-Stage): These paddles scoop and throw snow. Many models have wear indicator holes; when the paddles wear down to these holes, it’s time for replacement.

- Skid Shoes (Two-Stage): Located on each side of the auger housing, these adjustable plates prevent the auger from scraping the ground. They are designed to wear and are often reversible. Once both sides are worn, replace them. Adjust them properly for your surface type (e.g., gravel vs. paved).

Essential Engine Care for Peak Performance

The engine is the heart of your gas-powered snow blower. Proper care of the fuel, oil, and ignition system is non-negotiable for reliable starts and smooth operation. Most engine problems are preventable with these snow blower maintenance tips.

The Role of Fuel and Stabilizer

Old, untreated gasoline is the number one cause of starting problems. Fuel can degrade in as little as 30 days, forming sticky deposits that clog the carburetor and fuel lines.

To prevent this, always use fresh gasoline (87 octane or higher) with no more than 10% ethanol (E10 maximum). Higher ethanol content can damage small engines. Buy only what you’ll use within a month.

Fuel stabilizer is your secret weapon. Add it to your gas can immediately after filling it. After adding stabilized fuel to your snow blower, run the engine for five minutes to circulate the treated fuel throughout the entire system, protecting the carburetor, fuel lines, and tank.

How to Change Snow Blower Oil

Engine oil becomes contaminated with moisture and debris, reducing its ability to lubricate. An annual oil change is crucial for engine longevity.

Change your oil once per season. New machines need their first oil change after just 5 hours of use. After that, check your oil level every 5 hours of operation. For New England winters, winter-grade 5W-30 synthetic oil is the best choice as it flows better in cold temperatures.

To change the oil:

- Warm the engine for 5-10 minutes so the oil drains completely.

- Place a catch pan under the drain plug and remove the plug.

- Let the oil drain completely, then replace the plug securely.

- Slowly add fresh oil, checking the dipstick frequently to avoid overfilling.

- Dispose of used oil properly at an authorized recycling center.

For a step-by-step visual guide, watch this helpful video: How to Change Engine Oil on a Two-Stage Snowblower.

Checking and Replacing the Spark Plug

A clean, functional spark plug provides the spark needed for ignition. A fouled or old plug leads to starting issues and inefficient fuel use.

Replace your spark plug every 100 hours of operation or once per season. Before each season, inspect it for heavy corrosion, oily residue, or cracked porcelain.

When installing a new plug, apply a thin coat of anti-seize compound to the threads to prevent it from seizing. Thread the new plug in by hand first to avoid cross-threading, then tighten with a wrench. Set the proper spark plug gap according to your manual (usually 0.020-0.030 inches) using a gap tool. A fresh spark plug is a small investment that pays big dividends in reliability.

Key Mechanical Checks and Snow Blower Maintenance Tips

Beyond the engine, the mechanical systems that gather and throw the snow need regular attention to handle the heavy, wet snow common in New England. Neglecting these parts can lead to frustrating mid-storm breakdowns.

Inspecting Belts and the Pull Cord

Belts transfer power from the engine to the auger and wheels. A worn belt can snap, leaving you stranded. Before each season, inspect the auger and drive belts for:

- Cracks running along the belt’s surface.

- Fraying along the edges.

- Glazing (a shiny, slippery surface) that indicates slipping.

Also, check your starter cord for fraying. A frayed cord can snap when you need it most. We recommend keeping these spare parts on hand: shear pins, a spark plug, and a drive belt.

The Importance of Shear Pins

Shear pins are a critical safety feature on two-stage snow blowers. These small bolts are designed to break if the auger hits a hard object like a rock or a chunk of ice. This sacrificial action protects the expensive gearbox from catastrophic damage. When a shear pin breaks, the auger stops turning while the engine continues to run.

Always keep spares on hand and use only the exact manufacturer-recommended replacement. Using a standard bolt can lead to severe gearbox damage. To replace a shear pin, turn off the engine, disconnect the spark plug wire, remove the broken pieces, align the holes, and insert the new pin, securing it with its clip.

Lubrication and Rust Prevention

Proper lubrication keeps moving parts from seizing and protects against rust from salt and moisture.

Key lubrication points include:

- Auger shaft grease fittings (zerks): Use a grease gun to apply grease until it just begins to ooze out.

- Wheel axles: Remove wheels annually and apply a thin layer of grease or anti-seize compound.

- Drive gears and chains: Check your manual for access points and lubricate as needed.

- Chute rotation gears: A little grease here prevents the chute from getting stuck.

To prevent corrosion, wipe down metal surfaces after each use, especially after clearing salty slush. At the end of the season, wash the entire machine, dry it thoroughly, and touch up any paint chips to prevent rust.

For comprehensive winter preparation tips that complement your snow blower maintenance, check out our guide on Home Heating Safety Tips.

Preparing for Hibernation: End-of-Season Storage

How you store your snow blower is just as important as pre-season prep. Proper storage prevents rust, fuel system clogs, and ensures it’s ready for next year. A little effort now saves you from major headaches when the first nor’easter hits.

Final Fuel System Prep

Leaving untreated fuel in the tank over the summer is a recipe for disaster, as it turns into a gummy mess that clogs the carburetor. You have two options for safe storage:

- Run the Engine Dry: Siphon or pump most of the gasoline from the tank. Then, start the engine and let it run until it stops from lack of fuel. This burns any remaining gas from the carburetor and fuel lines.

- Use Stabilized Fuel: If you prefer not to run it dry, fill the tank completely with fresh gasoline treated with a high-quality fuel stabilizer. A full tank prevents rust from forming inside and keeps gaskets from drying out. Run the engine for a few minutes to circulate the treated fuel through the system.

Clean and Protect

Road salt and grime are corrosive. A thorough cleaning protects your investment.

- Wash and Dry: Use mild soap and water to scrub down the entire machine, especially the auger housing and chute. Dry it thoroughly to prevent rust.

- Inspect and Touch Up: Look for any paint chips or scratches on the metal. Touch up these bare spots with rust-inhibiting primer or paint to stop rust before it starts.

- Lubricate: Apply a light coating of multi-purpose oil or silicone spray to exposed metal parts like the auger and impeller to create a barrier against moisture.

- Store Properly: Keep the snow blower in a dry, covered location like a garage or shed, away from heat sources. A snow blower cover offers extra protection from dust and moisture.

Taking these steps transforms storage into an investment in next winter’s success. For more seasonal maintenance wisdom, check out our Spring Home Maintenance guide.

Frequently Asked Questions about Snow Blower Maintenance

What are the most critical snow blower maintenance tips for a beginner?

For beginners, focus on three key areas to prevent 90% of common problems:

- Fuel: Always use fresh gasoline with a fuel stabilizer. Old, untreated fuel is the #1 cause of starting issues.

- Oil: Check the engine oil level before each use and change it once per season.

- Cleaning: After each use, clean all snow and ice from the machine to prevent rust, corrosion, and frozen parts.

How do I safely unclog my snow blower’s chute?

Safety is paramount. First, turn off the engine and wait for all moving parts to stop completely. Never use your hands or feet to clear a clog. Use the plastic clean-out tool that came with your machine or a sturdy broom handle. For maximum safety, disconnect the spark plug wire before clearing the blockage to eliminate any chance of an accidental start.

How often should I have my snow blower professionally serviced?

While you can do most routine maintenance, a professional tune-up every two to three seasons is a good investment. A technician can perform complex tasks like carburetor adjustments and valve clearance checks. You should definitely call a pro if you have persistent starting problems despite using fresh fuel and a new spark plug, or if you hear strange grinding noises from the engine or auger.

Protect Your Investment for Winters to Come

Following these snow blower maintenance tips provides peace of mind during unpredictable New England storms. You’ve invested in a quality snow blower; with consistent care, that investment can serve you reliably for decades.

A well-maintained machine doesn’t just clear your driveway—it protects your family’s safety and your property’s accessibility. A clear driveway is essential for safe passage and emergency vehicle access.

Protecting your valuable assets, from your home to the tools that maintain it, is a cornerstone of responsible homeownership. Just as you protect your home and car, your equipment deserves the same thoughtful protection. Proper insurance coverage is just as important as a well-tuned machine. The team at Stanton Insurance Agency understands the unique challenges New England homeowners face and we’re here to help you protect what matters most.

Whether you need guidance on home coverage that protects against winter damage or want to ensure your valuable equipment is properly covered, we’re here to help. Contact Stanton Insurance Agency to discuss how we can help safeguard your investments, or learn more about our home insurance services.